Common Printing Processes, Basic Techniques, and Equipment

Printing serves as the primary means for communication between products packaged in composite flexible packaging and consumers. The main printing methods for flexible packaging are gravure printing and flexographic printing. With technological advancements, environmentally friendly and personalized market demands are met through techniques like UV and EB ink printing, as well as the flexible digital printing method. The five essential elements of printing include original graphics, printing plates, ink substrates, and printing machinery. Below, we will introduce several different factors in detail.

I. Gravure Printing

Gravure printing is currently the dominant printing method in China and the Asian region's flexible packaging industry. Its exquisite and delicate printing effect attracts consumers' attention effectively, meeting market demands. Moreover, the technology is mature, including plate-making techniques. Gravure printing is cost-effective in China, while the printing equipment is relatively affordable. Skilled operators proficient in gravure printing technology are also readily available. Hence, since the late 1980s until now, gravure printing has firmly remained the mainstream printing method in China's composite flexible packaging industry, with a market share exceeding 96%. This is distinct from the industry trends in Europe and America.

The development of gravure printing technology traces back to the mid-15th century with the manual engraving of gravure plates. In 1452, an Italian goldsmith applied engraved copper plates. The etched intaglio plate technique developed in the 17th century, followed by mechanical engraving. A German inventor invented photogravure plates in 1890, and doctor-blade gravure in 1892 which became widespread globally in 1910 and was utilized for newspaper printing in Germany in 1912 and for printing pictures in the New York Times in 1914. After a slowdown due to the impact of World War II, gravure printing experienced significant development. In the 1960s, gravure printing technology got matured further.

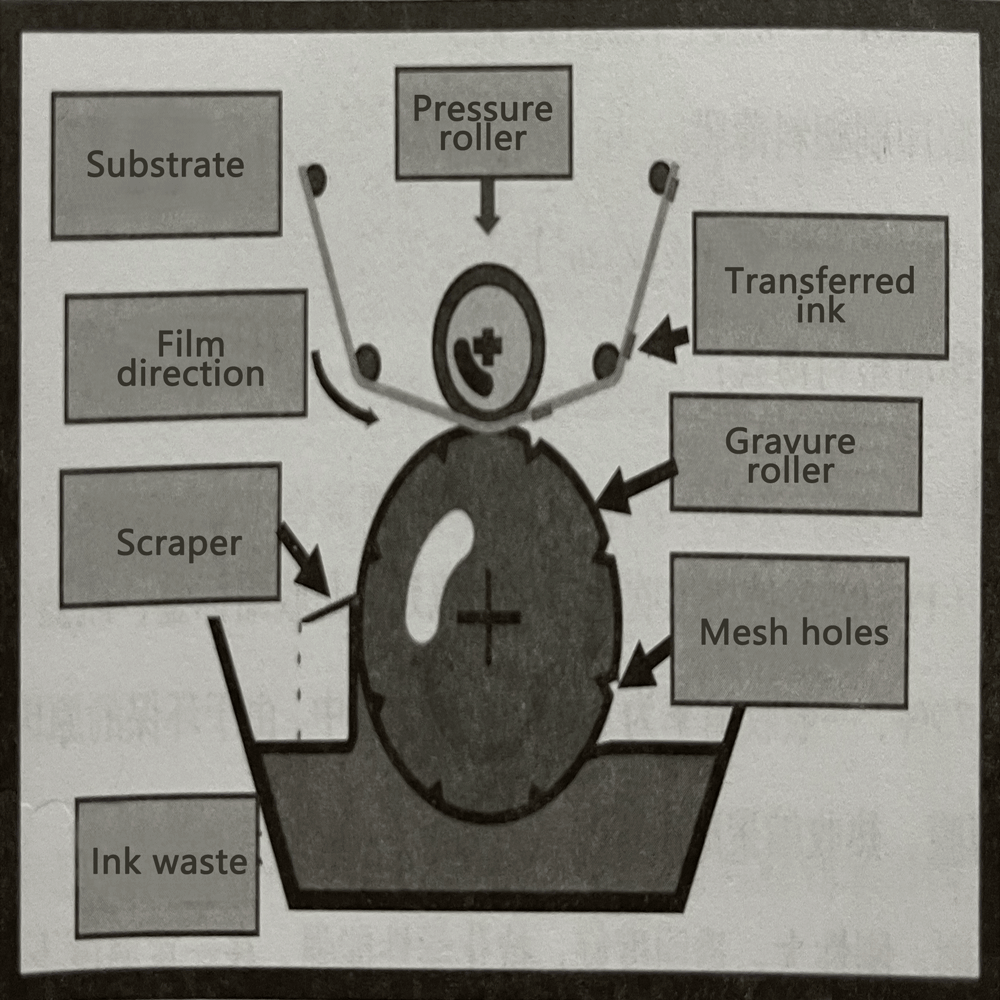

(I) Gravure Printing Principles

Gravure printing requires to make plates in advance based on the color separation of the original graphics . The plate-making processes include mechanical machining, copper plating, chromium engraving, and polishing. Engraving techniques include electric engraving, laser engraving, Laser etching and photochemical etching, and so on.

During printing, the printing cylinders are partially immersed in ink, filling the cylinder's cells. Excess ink is removed using a doctor blade, leaving ink only in the cells. The substrate and the printing cylinder make contact under pressure, transferring ink from the cells to the substrate surface. This process is repeated for each color, layering colors to achieve the final printed pattern and text.

The primary printing substrates for flexible packaging are plastic films such as PET, BOPP, PE, and NY. However, in pharmaceutical packaging, printing on aluminum foil is common. Printing in composite flexible packaging is categorized into surface printing (top printing) and reverse printing (inside printing). These substrates possess varying mechanical properties, requiring different printing methods. Generally, biaxially oriented substrates are used for gravure printing, while non-stretched PE materials are more suited for flexographic printing. In North America, flexographic printing accounts for over 80% of the market share in the flexible packaging industry, whereas in Europe, it exceeds 60%.

(II) Gravure Printing Materials

Common gravure printing plastic films include:

(1) Non-Stretched Gravure Printing Plastic Films, mainly used for surface printing:

• Low-Density Polyethylene Film (LDPE: density: 0.910~0.925 g/cm³)

• Medium-Density Polyethylene Film (MDPE: density: 0.926~0.940 g/cm³)

• High-Density Polyethylene Film (HDPE: density: 0.941~0.965 g/cm³)

• Polypropylene Film (PP: density: 0.91 g/cm³)

(2) Biaxially Oriented Gravure Printing Films:

• Biaxially Oriented Polypropylene Film (BOPP: density: 0.91 g/cm³)

• Biaxially Oriented Pearlized Film (BOPL: density: 0.60~0.70 g/cm³)

• Biaxially Oriented Polyester Film (BOPET: density: 1.40 g/cm³)

• Biaxially Oriented Nylon Film (BOPA: density: 1.15 g/cm³)

(3) Uniaxially Cast Gravure Printing Plastic Films:

Uniaxially Cast Polypropylene Film (CPP: density: 0.91 g/cm³)

(4) Heat-Shrinkable Gravure Printing Plastic Films:

①Heat-Shrinkable Polyolefin Films: PVC, PE, PP, POF (PP+PE) are extrusion blow molding or extrusion cast molding, protective packaging for shrink labels, bottle caps. The shrinkage rate ranges from 15% to 75%, generally around 40% to 50%. Due to environmental concerns, PVC film usage is decreasing.

②Heat-Shrinkable Polystyrene Films, Heat-Shrinkable Polyethylene Films: PET, OPS shrink films are easy to print, have high rigidity, excellent transparency, and strong chemical resistance. The shrinkage rate ranges from 15% to 75% at a certain temperature, generally around 40% to 50%.

(5) Common Gravure Printing Papers:

①Gravure Printing Papers for Food and Pharmaceutical Packaging: Parchment paper, medical paper, white cardboard, etc. are composed of pulp fibers, additives, and water. Pulp fiber is divided into plant fiber and non-plant fiber, while plant fibers are classified into wood fibers and non-wood fibers, including secondary fibers. Basic paper properties include grammage, compactness, stiffness, whiteness, smoothness, roughness, moisture content, etc. Papers for food and pharmaceutical gravure printing are generally made of all-wood pulp.

②Other Gravure Printing Papers: Shopping bag gravure printing papers usually use long fiber pulp to reduce damage, enhance strength and enable recycling. Fiber length typically ranges from 3mm to 8mm.

(6) Common Aluminum Foil in Soft Packaging: Some food and pharmaceutical packaging utilize high barrier materials like aluminum foil, which requires surface printing or gravure printing for applying heat-seal coatings or glossy varnishes. Aluminum foil thickness typically ranges from 0.007 to 0.020mm.

In the field of composite flexible packaging, LD PACK takes pride in its advanced printing technology and high-quality printing products. We use the most advanced gravure printing technology, combining years of experience and innovation to provide exceptional print quality and visual effects to our clients.

LD PACK covers various common gravure printing plastic films, including Low-Density Polyethylene Film (LDPE), Medium-Density Polyethylene Film (MDPE), High-Density Polyethylene Film (HDPE), and others. Additionally, we possess biaxially oriented gravure printing films like Biaxially Oriented Polypropylene Film (BOPP) and Biaxially Oriented Pearlized Film (BOPL), as well as uniaxially cast gravure printing plastic films like Cast Polypropylene Film (CPP).

LD PACK is dedicated to offering top-quality printing solutions in the field of flexible packaging. Our professional team and advanced equipment ensure that your products stand out in the market, gaining customer trust and satisfaction.