Effective measures to solve aluminum coating transfer

The correct way to solve the aluminum coating transfer: ensure the qualified adhesion between aluminum coating and the substrate, and reduce the stress between each layers of lamination.

Solution | Operation |

Ensure the qualified adhesion between aluminum coating and the substrate | Test the adhesion of aluminum coating: use 3M tape and EAA heat seal for pre-use test |

Reduce the stress between each layers of lamination | |

Control tension properly | |

Use adhesive correctly |

(1) Ensure the qualified adhesion between aluminum coating and the base film

Choose the aluminum coating with better adhesion is a effective measure to solve the aluminum coating issue.

In actual production, the enhanced metalized film will be selected to solve the severe aluminum coating transfer. For example, when producing enhanced VMPET film, PET film with chemical coating treatment is used as the base film to improve the adhesion of aluminum coating layer. But in this case, the cost is much higher. So for the general packaging, we must first check whether the quality of metalized film we purchased is qualified and up to standard.

(2) To reduce the interlayer stress of the laminates, it is suggested to improve from the following two aspects:

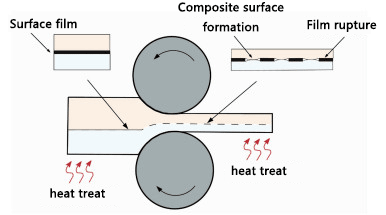

① Internal stress generated by the laminated tension

Control the laminated tension: avoid the mechanical stress caused by the mismatch of tension exerted on two substrate when laminating. Whether the laminated film is "crimped" is a direct method to determine whether the laminated tension is matched. That means, place the laminated sample without curing on the table for cross cutting. If the laminated film curled in any direction, it indicates that the tension in this direction is large, and there is a "mechanical stress" in the lamination.

Pay attention to the hot-shrinkage rate of the laminated film itself:

In the later heat treatment process, different base films will generate different shrinkage rates under the corresponding treatment temperature conditions, which will cause thermal shrinkage stress.

There are two way to test the thermal shrinkage rate of laminated film:

• Dry heat test conditions: put the film into the dry heat condition at 150~200℃ and store it at constant temperature for 5 minutes, then test and compare the shrinkage changes before and after.

• Hot water test conditions: put the film into the hot water at 100℃ for 5 minutes, then take it out. Test and compare the shrinkage changes before and after.

Therefore, reduce the crimbiness (mechanical stress and thermal stress) of the laminated film after put into machine or curing, can effectively reduce the transfer of aluminum coating caused by the stress between the films.

② Adhesion & peeling strength

Usually can improve from the following three aspects:

a. Choose the glue model with soft colloid and excellent performance to reduce the mechanical stress on the aluminum coating layer;

b. Lower curing temperature: effective improve the shrinkage ration of the laminating materials and reduce the stress on the aluminum coating layer;

c. How to use adhesive correctly:

• Choose adhesives with appropriate flexibility and extensibility.

• Adopt the appropriate two-pack glue ratio: when the glue is prepared, reduce the amount of curing agent appropriately, so that the crosslinking reaction of the main agent and curing agent is reduced as well, resulting in reduction of the brittleness and stress in the laminated film.

• Ensure the coating uniformity and the amount of glue: keep the minimum amount of glue, make it uniform on the base film, avoid generating white spots and bubbles when put into the machine, so as to reduce the stress in the laminated film.

• Aluminium coating & gluing process: Especially when there is no solvent, use the appropriate aluminum coating and gluing process to enhance the uniformity of glue coating and reduce the risk of white spots.

• Curing process: Low temperature curing can be used to reduce the influence of excessive internal stress caused by high temperature shrinkage of the inner film.