Roasted Seeds & Nuts - Composite Film Structural Design

The packaging of consumed foods can be divided into convenient food, puffed food, pastries & biscuit, dairy product & baked goods, candy & preserved fruit, meat product, pre-made food, roasted nuts, frozen food,health care, grain & oil, sauce, wine & beverage, tea & instant drink etc.

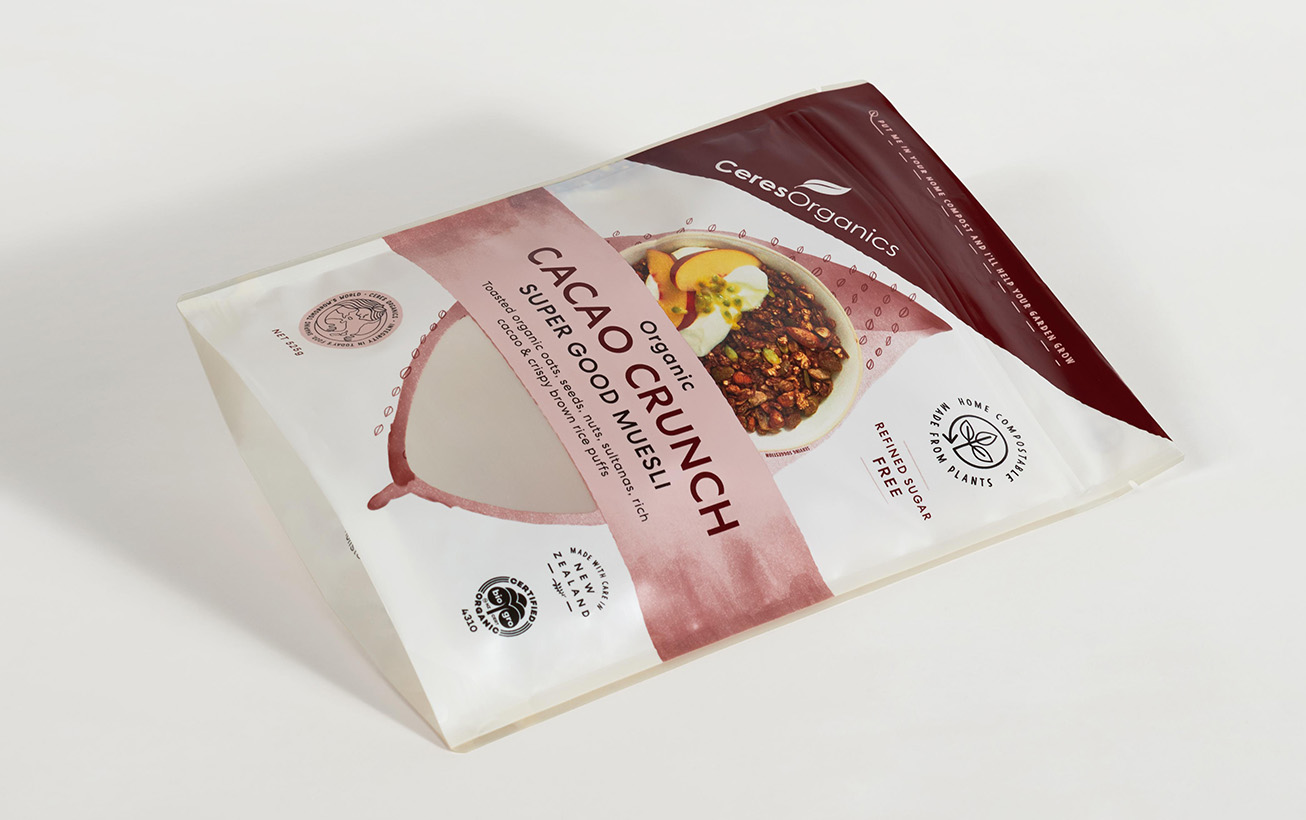

Roasted Seeds & Nuts

1. Food Type

Peanuts, nuts, beans, red dates, green beans, cashews, melon seeds, daily nuts etc.

2. Packaging Requirements

(1) High Barrier: Food has high fat content, which is easily oxidized and deterioration, resulting in bad smell and taste and decreasing its nutritional value. So the food packaging must be high oxygen barrier. The roasted seeds and nuts are low in water, and they are easy to be damp and decrease in crispiness. What’s more, the the increase of water content would accelerated the fats and oils oxidation. So it is required a packaging with high moisture barrier to keep the food dry and inhibit the microbial proliferation.

(2) Good Aroma Retention: Prevent aroma loss during the shelf life.

(3) Gas Filled Packaging: The packaging is filled with certain proportion of gas like N2, CO2 to prevent the oxidation.

(4) Light Resistance: Ultraviolet light is also an important reason for the deterioration of oil photo-oxidation, therefore, some packaging is required a certain light resistance.

(5) High Puncture Resistance: There may be sharp objects inside packaging of roasted nuts. The packaging pouch will be punctured easily during transportation, resulting in food spoilage. So the packaging must be high puncture resistance.

(6) High Heat Sealability:It has high sealing performance against impurities.

(7) High Peeling Strength: The peeling strength between the laminate layers is low, even delaminated, which would weaken the material integration of all layers, such as heal-sealing strength, tensile strength and impact strength etc. Easily result in poor use when the packaging suffers external force.

(8) Good Sealing: If the packaging pouch is broken or there’s a gap in the heal seal, the water and oxygen would seep into the pouch, resulting in food spoilage.

(9) Low Residual Solvent: The residual solvent in the packaging film may be slowly seep into the food, so we must minimize the residual solvent in food packaging as possible as we can.

(10) Suitable Right Angle Tearing: It is easy to tear the pouch when use, easy to eat.

(11) Good Flexibility:When vacuuming, the packaging will be attached to the surface of the contents, and it's required to make sure no air leakage at the crease.

(12) Rub Resistance: Prevent the reduction of barrier performance due to the tiny holes caused by rubbing.

(13) Dry & Wet Contents Separation: The mixed nut fruits are divided into dry and wet parts, which are required separation before eating. Otherwise, the dry nut fruits easily become damp, while the wet part loses water.

3. Structure of Packaging Film

NY/CPP; OPP/CPP; PET/CPP; NY/LDPE; PET/LDPE; OPP/VMPET/LDPE; Matt OPP/VMPET/LDPE; OPP/VMCPP; PET/AL/NY/CPP; PAP/PE/AL/LDPE; PAP/PE/VMPET/LDPE; OPP/VMPET/Modified PP.

LD PACK provides customers with professional advice on customized food packaging in accordance with their needs and uses. With 30 years of packaging experience, thanks to its profession and sincerity, LD PACK have established long-term cooperative relationships with many well-known brands in the world, such as Nestlé, Mars, Heinz, Fonterra etc.

If you are looking for a professional customized pouch supplier, LD PACK should be your best choice.

We will continue to discuss more about the food packaging in next episode. Please follow us and see what will be the next hot topic of food packaging. Look forward to your attention!