Pet Food Packaging Solutions

- LD PACK

- China

- PET/PE; PET/NY/PE; PET/AL/NY/PE; PET/MPET/PE

- Dog foods, cat foods, any pet foods

- We have enough machinery and equipment for production to reach 350 tons per week.

- 30,000 PCS

- 30 days lead time

Discover a new era of pet food packaging that aligns with your values.

More than just packaging, our solutions represent a shared commitment to a sustainable future.

By opting for recyclable packaging, you're making a powerful statement – that the health of your pets and the health of the environment are intertwined.

Market Requirements

With the deepening of scientific pet rearing, consumers' demand for pet food is becoming more and more diversified. They care about not only the pet food quality, but also the environment protection. Therefore, the brand owners make greater demands of packaging to meet the needs of pet owners preferably.

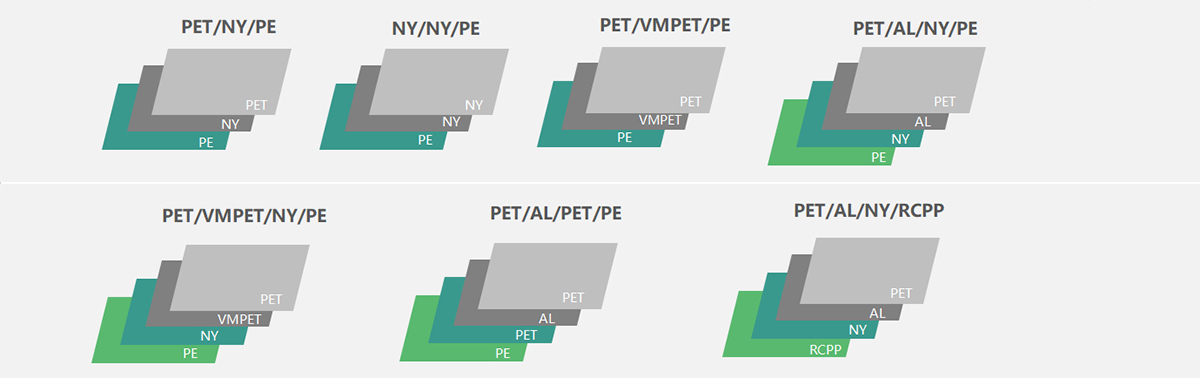

Traditional Composite Structure Solutions

Ø The traditional composite structure solution is a kind of packaging based on product performance, cost and production benefit.

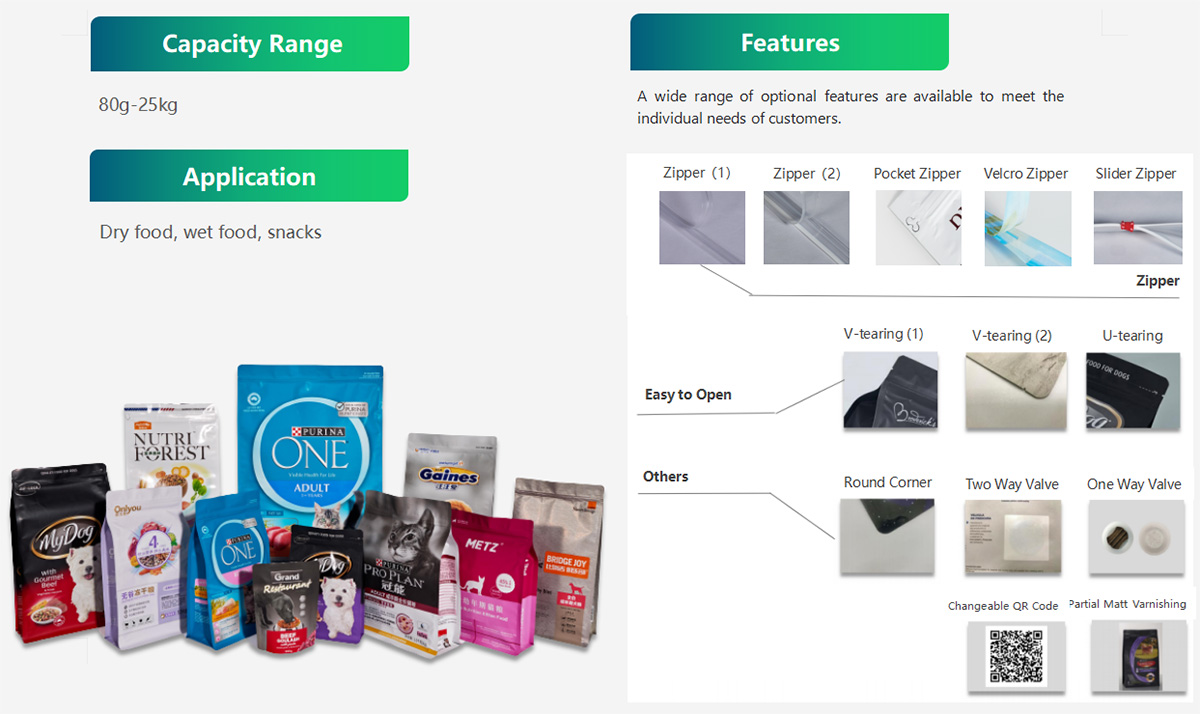

Ø LD PACK has a keen appreciation for the influence factors of pet food, such as preservative, packaging, storage condition(temperature/light) etc. Especially, the barrier properties of packaging play a crucial role in the shelf life of pet food. Therefore, we accordingly customize the barrier material for different shelf requirements of specific products, providing customers with the perfect packaging solutions

Ø Variety of feature options are available in each part of production, helping customers to build differentiated high-end brand image.

Material Structur

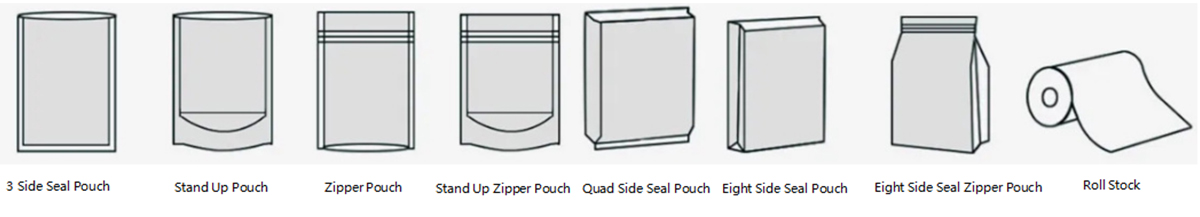

Pouch Type

Recyclable Packaging Solutions

Ø For the pet food market, LD PACK provides recyclable packaging of mono PE, mono PP, mono PO etc.,covering pouch type of roll stock, flat bottom zipper pouch, stand-up pouch, retort pouch and spout pouch etc. The package is suitable for full automatic, semi-automatic or manual filling.

Ø LD PACK recyclable packaging solutions strictly adhere to Designing for a Circular Economy Guidelines issued by European Sustainable Organization, while maintaining the excellent performance of traditional composite structures.The recyclable packaging is free of PET, PVC, PVDC and aluminium foil.

Ø At present, the recyclable packaging has been mass-produced for the top brands of pet food, like Nestlé, Mars and brought to the market. We are working hard too provide more suitable and innovative recyclable packaging solutions to the pet food companies at home and abroad.

Application Cases

Mono PE Recyclable Packaging-Stand-up Zipper Pouch

Facts:

●≥95% PE Based packaging

●Single layer PE film

●Good water vapor resistance

Applications:

●Pet food packaging,frozen food, snacks food,fresh food

Mono PP Recyclable Packaging-Flat Bottom Pouch

Facts:

●≥95% PP Based packaging

●High strength PP film

●Chlorine free

Applications:

●Coffee, pet food packaging,snacks food

Mono PP Recyclable Packaging-Stand-up Retort Pouch

Facts:

●≥95% PP Based packaging

●High barrier PP film

●No metallic aluminum, OTR≤0.5

●Hot fill or pasteurization

●Retortable 121℃

Applications:

●Rice, tuna, sauce, pet food

Mono PO Recyclable Packaging-Flat Bottom Zipper Pouch

Facts:

●≥95% PO based packaging

●Good recyclable in PO recycling

●Performance combined with PP/PE

●Metallized PP film, OTR≤1

Applications:

●Coffee, snacks food, pet food, Tea

Co-brands

As a enterprise with over 30 years of experience in flexible packaging production, LD PACK has established a long-term and stable partnership with lots of well-know brands at home and abroad.

Our professional team is working hard on innovation and provide better packaging solutions to meet the requirements of pet food market.

No matter which solution you refer, LD PACK is always the first choice to be your best business partner. Contact us now and you will get your Exclusive customized solutions.

1.What factors should I consider when selecting packaging materials for pet food?

2.How do moisture and oxygen barrier properties impact packaging material selection?

3.What are the differences between Mono-material and composite structure packaging?

Mono-material packaging is made from a single type of material, such as paper, polyethylene (PE), polypropylene (PP), etc.

This type of packaging is homogeneous, containing only one type of material.

Mono-material packaging is typically easier to recycle and reuse since the material is homogeneous and doesn't require separation and sorting.

Composite structure packaging is composed of multiple layers of different types of materials, such as polyethylene terephthalate (PET)/polyethylene (PE)/aluminum foil (AL), etc.

This packaging is designed with different material layers to provide specific performance and functionalities, such as moisture resistance, oxygen barrier, light protection, etc.

Composite structure packaging is often used for products that require enhanced protective properties, but it may add complexity to recycling and reuse due to the diversity of materials involved.

4.What are the common composite structures used in pet food packaging?

1.PET/PE: A combination of polyethylene terephthalate (PET) film and polyethylene (PE) film, typically used for pet food packaging, providing good sealing and moisture resistance.

2.PET/AL/PE: A three-layer composite structure consisting of PET film, aluminum foil (AL), and PE film, often used for high-demand pet food packaging such as dry food and biscuits, with moisture resistance, oxygen barrier, and light protection properties.

3.NY/PE: A combination of nylon (NY) film and polyethylene (PE) film, suitable for frozen pet food packaging, popular for its excellent low-temperature performance.

4.PA/PE: A combination of polyamide (PA) film and polyethylene (PE) film, commonly used for pet food bags requiring high strength and tear resistance.

5.PET/MPET/PE: A three-layer structure comprising PET film, metallized polyester (MPET) film, and PE film, suitable for heat-seal packaging, offering good moisture resistance and light protection.

5.How do I choose the right packaging materials for my pet food products?

6.How does packaging affect the shelf life of pet food?

7.How to make packaging perform better on the shelf and enhance the customer experience?

1.Eye-Catching Design: Create a visually appealing and distinctive packaging design to make your product stand out among competitors.

2.Clear Product Information: Ensure that clear product information is displayed on the packaging, helping customers understand the product's use and features.

3.User-Friendly Packaging: Design packaging that is easy to open and reseal, enhancing the overall customer experience.

4.Brand Consistency: Maintain brand consistency by using consistent logos and design elements to improve brand recognition.

5.Sustainability: Consider eco-friendly packaging materials and designs to attract environmentally-conscious consumers.

8.How does MONO-material packaging address issues in the printing and bag-making production process?

Mono-material packaging is typically simpler because it is made from a single type of material. This helps streamline the printing and bag-making production processes, reducing material complexity. Here are potential issues and solutions:

a. Printing: Mono-material packaging is usually compatible with various printing techniques such as flexographic printing, offset printing, digital printing, etc. Choosing the appropriate printing technology ensures printing quality.

b. Bag-Making: The bag-making process for mono-material packaging is relatively straightforward and usually does not involve the preparation of multiple complex layers. Therefore, bag-making processes can be more efficient.

c. Quality Control: Ensure the selection of high-quality materials and printing processes to minimize defects during production, and implement quality control measures.

9.How much more expensive is mono-material packaging compared to composite structure packaging?

Mono-material packaging is generally relatively cheaper because it utilizes a single type of material, simplifying the manufacturing and processing processes.

Composite structure packaging may be more expensive as it involves multiple different types of materials and requires more processes and technologies for production.

However, the cost difference will vary based on factors such as the size of the packaging, material quality, and complexity.

For some specific requirements, composite structure packaging may be indispensable as it can provide enhanced protective properties.

Therefore, cost differences should be assessed based on the specific packaging project.

10.How can I ensure the packaging is suitable for transportation and storage?

11.Detailed list of materials commonly used in pet food flexible packaging

| Material | Description | Layer | Performance |

|---|---|---|---|

| PET (Polyethylene Terephthalate) | Transparent, tear-resistant, rigid | Outer layer | OTR: 2-5 cc/m²/day (25°C, RH 0%), WTR: 0.1-0.4 g/m²/day (38°C, 90% RH) |

| PE (Polyethylene) | Water-resistant, flexible, chemical-resistant | Inner layer, sealing layer | OTR: 120-150 cc/m²/day (25°C, RH 0%), WTR: 0.8-1.5 g/m²/day (38°C, 90% RH) |

| AL (Aluminum Foil) | Light-proof, oxygen and water vapor barrier, extended freshness | Intermediate layer | OTR: < 0.01 cc/m²/day (25°C, RH 0%), WTR: < 0.01 g/m²/day (38°C, 90% RH) |

| NY (Nylon) | High strength, tear-resistant, puncture-resistant, used for frozen food packaging | Inner layer, moisture-resistant layer | OTR: 3-5 cc/m²/day (25°C, RH 0%), WTR: 0.6-1.0 g/m²/day (38°C, 90% RH) |

| PA (Polyamide) | High-temperature resistant, high strength, often used in vacuum packaging | Inner layer | OTR: 1-3 cc/m²/day (25°C, RH 0%), WTR: 0.4-0.8 g/m²/day (38°C, 90% RH) |

| MPET (Metallized Polyester) | Oxygen and light barrier, improved shelf life | Intermediate layer | OTR: < 0.01 cc/m²/day (25°C, RH 0%), WTR: < 0.01 g/m²/day (38°C, 90% RH) |

FAQ

Are you a manufacturer?

Yes, we have more than 25 years experience in flexible packaging from 1990.Including Packaging bags, Plastic bag / Stand up Pouch/Spout bags/Ziplock bags/ Food Packaging Pouch/Stand up Pouch with spout/ Plastic pouch/Black ziplock Pouch/Cookie bag/Popsicle Packaging/Ziplock bags

What information should I let you know if I want to get a quotation?

- Bag shape

- Dimension: Length x width (+ bottom/side gusset)

- Material structure and thickness, surface handling

If you are not sure, please let me know the effect you want and we will suggest.

- Printing colors, please also provide the artwork if possible

- Quantity

When we create the artwork, what kind of format is available for printing?

- AI, PSD, CORELDRAW, PDF