Cost-Effective Bag-in-Box Packaging for Wine, Juice, and Dairy

In the evolving landscape of food and beverage packaging, bag-in-box packaging has emerged as a highly cost-effective and sustainable solution. Initially popularized in the wine industry, the technology has expanded rapidly into categories such as juice, dairy, edible oils, and even condiments.

The benefits of this packaging format include reduced storage costs, extended product shelf life, convenient dispensing, and strong brand visibility. As consumer preferences lean toward sustainable packaging and producers look for ways to optimize logistics, the bag-in-box format is playing a critical role.

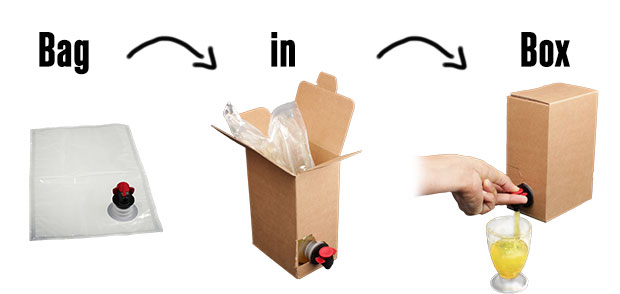

What is Bag-in-Box Packaging?

Bag-in-box (BIB) packaging is a system that consists of two main components:

The bag – usually made from multilayer flexible films that provide high barrier protection against oxygen, light, and external contaminants.

The box – a rigid outer layer, typically made from corrugated cardboard, designed to protect the bag during transport and storage, while also serving as a branding surface.

The inner bag includes a tap, spout, or fitment that allows for controlled dispensing of liquid without exposing the remaining contents to air, which significantly extends shelf life.

Why Bag-in-Box Packaging is Cost-Effective?

1. Lower Transportation and Storage Costs

Compared with traditional glass bottles or rigid plastic containers, bag-in-box packaging is lightweight and compact. A bulk shipment of wine, juice, or milk in bag-in-box form reduces overall freight costs. Empty BIB bags and boxes also require less storage space before filling, streamlining inventory management for producers and distributors.

2. Extended Shelf Life for Liquids

For sensitive products like wine and dairy, exposure to oxygen can lead to rapid spoilage. Bag-in-box technology minimizes oxygen contact thanks to its high-barrier films and sealed taps. Wine remains fresh for weeks after opening, juice maintains its natural flavor longer, and dairy products are less prone to bacterial growth.

3. Economies of Scale for Bulk Applications

Restaurants, catering services, and food manufacturers benefit from purchasing larger volumes in bag-in-box format. A 10L or 20L BIB pack of juice or milk is far more cost-efficient than handling multiple smaller containers. Bulk packaging reduces unit costs, simplifies operations, and provides consistent quality.

4. Optimized for Automation

Modern filling lines for bag-in-box packaging are highly automated, lowering labor costs and reducing errors. Bag-in-box [ackaging manufacturer provides technical support for automated filling equipment, ensuring efficiency and scalability for producers transitioning to BIB systems.

Applications of Bag-in-Box Packaging

1. Wine Packaging

The wine industry was the pioneer of bag-in-box adoption. The bag-in-box format allows consumers to enjoy wine at their own pace without spoilage, making it popular in markets like North America, Europe, and Australia. The large printable surface of the box provides excellent branding opportunities, which wineries leverage for eye-catching designs.

2. Juice Packaging

Juice producers face challenges with product freshness, distribution efficiency, and retail space management. Bag-in-box solutions offer a reliable way to preserve juices, especially those without preservatives. Juice brands catering to both retail and foodservice markets benefit from the cost-effective bulk packaging of 5L, 10L, and even 20L bag-in-box options.

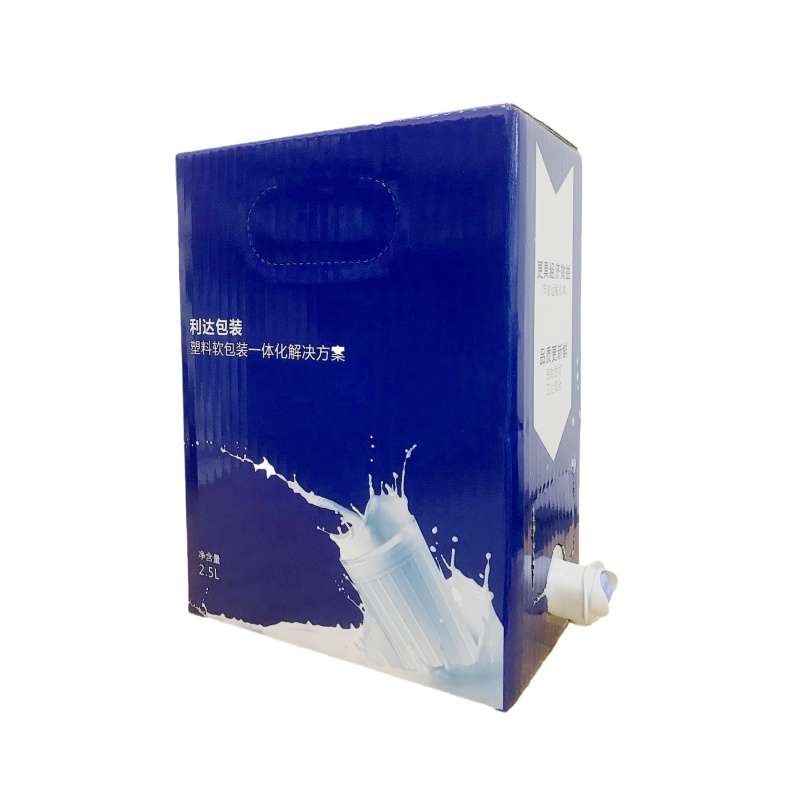

3. Dairy Packaging

Dairy products, including milk, cream, and yogurt-based beverages, demand strict hygiene and freshness. Bag-in-box packaging ensures sterile filling and dispensing, extending shelf life while reducing contamination risks. Large-scale buyers such as coffee shops, bakeries, and catering businesses increasingly prefer BIB dairy solutions due to their convenience and cost savings.

4. Beyond Wine, Juice, and Dairy

The versatility of bag-in-box packaging has led to expansion into:

● Edible oils

● Sauces and condiments packaging

● Washing liquid packaging

● Modified atmosphere packaging for fresh foods

These applications showcase the broad potential of bag-in-box technology across industries.

Bag-in-Box for Wine, Juice, and Dairy

Branding Opportunities with Bag-in-Box Packaging

The outer box of a bag-in-box system is a powerful canvas for brand storytelling. Unlike clear bottles that limit label space, BIB boxes offer multiple printable surfaces for logos, graphics, and product information. Bag-in-box packaging creates opportunities for:

● Premium product positioning in retail environments.

● Enhanced consumer engagement through QR codes and interactive designs.

● Consistent brand identity across multiple product lines.

Advanced printing technologies allow brands to create visually compelling packaging that boosts recognition and drives sales.

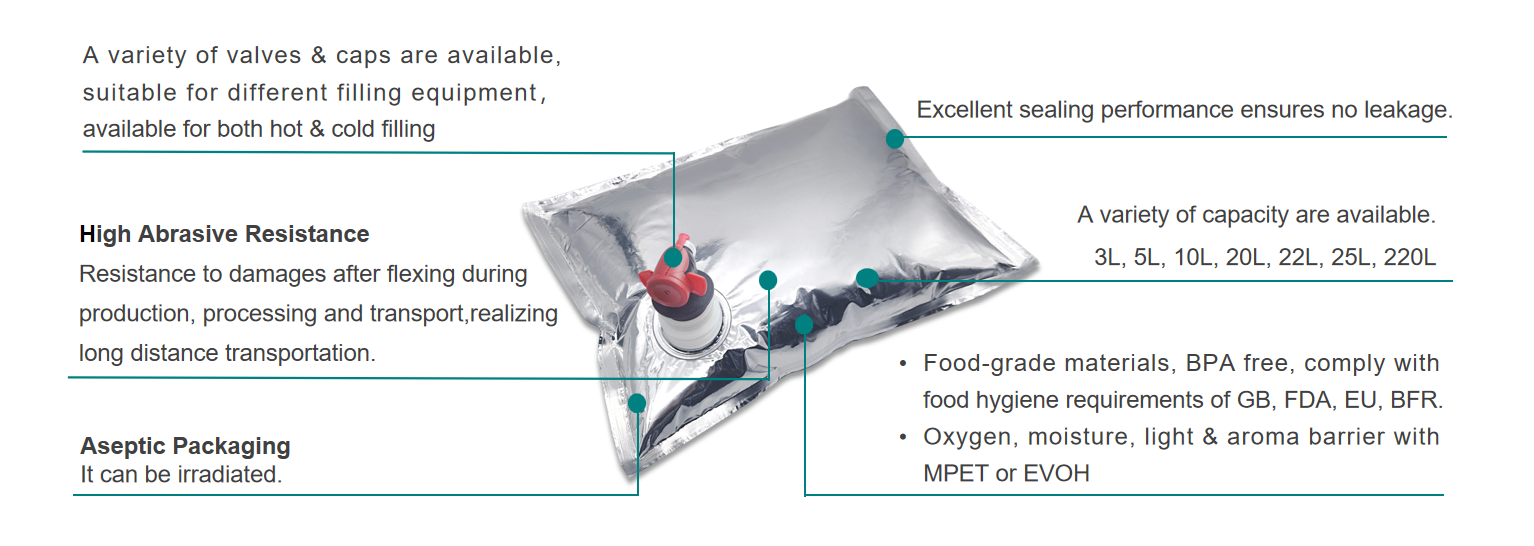

LD PACK Bag-in-Box Packaging Solution for Liquid

As a global leading manufacturer of flexible packaging, LD PACK has developed advanced bag-in-box solutions tailored to the needs of the wine, juice, dairy, and other industries.

Features

● Multi-Layer Film: Excellent barrier for extended shelf life

● Built-in taps or spouts for easy dispensing

● Leak-Proof Construction: Secure seals for safe transport

● Perfect for bulk packaging of liquids

Benefits

● Flat-packed for easy storage and transport

● Cost-Effective: Lower material and shipping costs vs. rigid containers

● Eco-Friendly: Less plastic, recyclable outer box

Materials

● Available in standard and custom structures

● Standard Structure: with or Without Metallization

● Eco-Friendly Options: Mono-material PE

The extensive product portfolio of LD PACK makes us a strategic partner for food and beverage brands looking for comprehensive packaging solutions. By working with LD PACK, you can ensure their products are not only well-protected but also aligned with consumer demands for cost-effectiveness and sustainability.

Frequently Asked Questions about Bag-in-Box Packaging

1. What is bag-in-box packaging, and how does it work?

Bag-in-box packaging consists of a flexible inner bag and a protective outer box. The bag is usually made of multilayer barrier film that preserves the product, while the box provides protection and branding space. A tap or fitment allows easy dispensing without letting air inside, which extends product freshness.

2. Why is bag-in-box packaging considered cost-effective?

It reduces transportation and storage costs due to its lightweight and compact design, minimizes product waste by extending shelf life, and lowers packaging material expenses compared to glass bottles or rigid plastic containers.

3. Is bag-in-box packaging suitable for wine?

Yes. Bag-in-box packaging keeps wine fresh for weeks after opening by limiting oxygen exposure. It’s also lighter, easier to transport, and has a large branding surface, making it popular with wineries worldwide.

4. How does bag-in-box packaging benefit juice manufacturers?

BIB packaging provides strong barrier protection, allowing juice to stay fresh longer. It’s also ideal for both retail sizes (3L–5L) and bulk catering packs (10L–20L).

5. Can dairy products be safely packaged in bag-in-box format?

Yes. Dairy products like milk and cream can be safely filled into sterile BIB bags. The sealed system reduces contamination risk and maintains freshness, making it a preferred choice for cafes, bakeries, and foodservice providers.

6. Is bag-in-box packaging sustainable?

Yes. It uses fewer raw materials than glass or rigid plastic, reduces carbon footprint through lightweight shipping, and allows for easy separation of the cardboard box and plastic bag for recycling. It also minimizes product waste.

7. What industries use bag-in-box packaging beyond wine, juice, and dairy?

Bag-in-box solutions are also widely used for edible oils, sauces, condiments, washing liquids, and even modified atmosphere packaging for fresh foods.

8. What sizes are available for bag-in-box packaging?

Common retail sizes range from 1.5L to 5L, while bulk applications use 10L, 15L, or 20L packs. Custom sizes can also be developed depending on customer needs.

9. Is bag-in-box packaging suitable for e-commerce and long-distance shipping?

Yes. Bag-in-box packaging is strong, compact, and durable, making it well-suited for direct-to-consumer shipping and export markets.

10. How does LD PACK support businesses using bag-in-box packaging?

LD PACK offers customizable designs, advanced barrier films, and sustainable material options. As a leading flexible packaging manufacturer, LD PACK ensures both efficiency and brand differentiation.

Conclusion

Bag-in-box packaging has proven itself as a cost-effective, sustainable, and versatile solution for industries such as wine, juice, and dairy.

In the fast-moving world of food and beverage packaging, choosing the right partner is as important as choosing the right packaging. For businesses looking to transition or optimize their packaging, LD PACK stands out as a trusted partner. Our expertise in flexible packaging and sustainable solutions ensures that you can achieve efficiency, maintain product integrity, and enhance your market presence.

Contact LD PACK at sales@ldpack.com to get your exclusive, customized bag-in-box packaging solution.